News

Articles & Recipes

Articles

When Changing Emulsifier Changes Everything

News

Articles & Recipes

Articles

When Changing Emulsifier Changes Everything

When Changing Emulsifier Changes Everything

In order to demonstrate some of these effects, we created a simple emulsion formula then substituted the emulsifier for a number of different options. The results of that experiment are shared below.

The Base Formula

When doing an experiment like this it is often preferable to keep the base formula as simple as possible as this avoids the potential for interactions between ingredients that may reduce or exaggerate the influence the emulsifier has on the formula.

With that in mind we opted for a cream that contained only water, glycerine and a gum-based thickener in the water phase and paired that with a simple one oil, one-emulsifier ingredient oil phase. We chose safflower as our oil as this is simple, cost-effective and typical of vegetable oil chemistry. We used 15% as that's within the typical range for a medium to rich day or light night cream.

As we wished to evaluate the impact of changing the emulsifier chemistry rather than its amount we kept the input level the same for each variant. We chose an amount that was within the recommended range for each of the four options to make things fair.

The formula was preserved with Plantaserv E - a Phenoxyethanol, Ethylhexylglycerin blend. We chose this as it is known to be less likely than other preservatives to disrupt the emulsion stability. Another benefit of this preservative is its ability to work across a wide pH range. We weren't changing pH too much in this experiment but it is useful to know the preservative is absolutely comfortable at the pH we are working with (4.5-6.5 before adjustments and 5-6 after).

Sample Preparation/ The Manufacturing Method

We used a typical two-pot process of preparing the oil phase and water phase separately, heating to 75-80°C and then pouring the oil phase into the water phase. A laboratory batch of 200g of each sample was made.

We used a propeller mixer to mix the samples while they cooled to 50°C and then added the preservative. The cream samples were then returned to the mixer and mixed until cooled to room temperature. The following day pH and viscosity were measured and any adjustments to bring the samples to a comparable pH of 5-6 was carried out using sodium hydroxide solution and citric acid.

The samples were then stored and re-analysed after five weeks.

| Ingredient | INCI | Percentage | Purpose |

| Water | Aqua | 76 | Solvent, continuous phase |

| Glycerine | Glycerin | 4.5 | Humectant |

| Acacia, Xanthan Gum | Acacia Senegal Gum, Xanthan Gum | 0.5 | Thickener, gelling agent, emulsion stabiliser. |

| Safflower Oil | Carthamus Tinctorius Seed Oil | 15 | Oil phase, emollient |

| Emulsifier | VARIOUS, SEE TABLE | 3 | Typical average amount of emulsifier |

| Plantaserv E | Phenoxyethanol, Ethylhexylglycerin | 1 | Preservative |

| pH Adjustment | Sodium Hydroxide/ Citric Acid | Qs | pH adjustment if needed |

| TOTAL | 100% |

The Evaluation

Sample evaluation was undertaken on two levels:

A.What can we see and feel on the outside and

B. Looking at what's going on inside of the emulsions

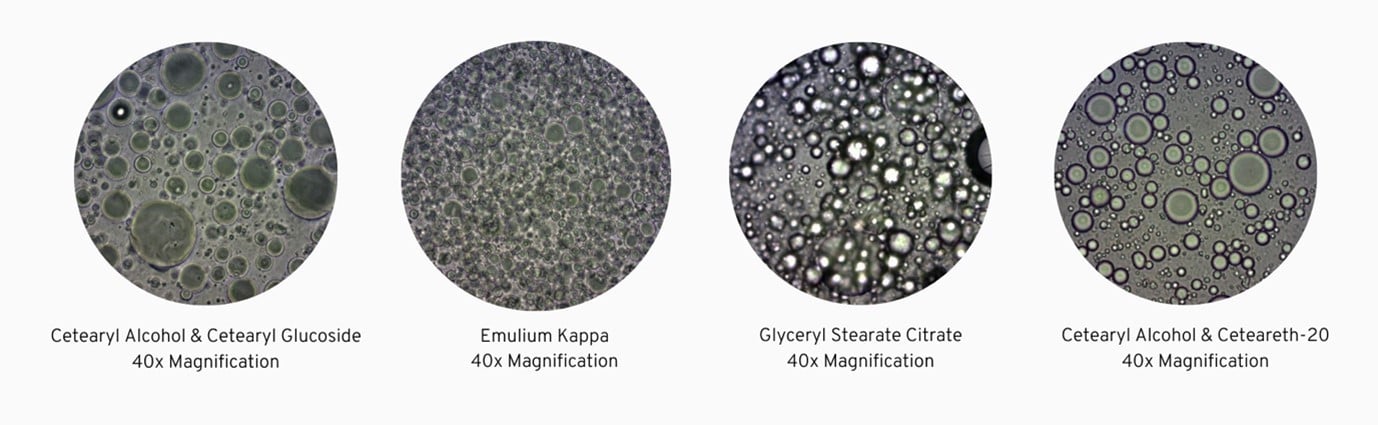

Looking at the emulsions under the microscope adds an extra layer of understanding to our evaluation. Microscopic analysis can help us work out if we have too much or not enough emulsifier. This can be helpful for optimising our formula costs and irritation potential. It can also help us see if our samples are homogenous (if the oil drops are all the same size). Emulsifiers that produce homogenous emulsions without the need for an extra homogenisation step are less expensive to manufacture. Taking a longer view, homogeneity or lack of alters the products chemical and physical stability, product efficacy and even how the product looks and feels (its aesthetics). The aim is to produce emulsions with a high level of homogeneity as these tend to perform better across the board.

Experiment Findings From The Outside In

It is worth noting that any evaluation of product aesthetics is somewhat subjective in as much as we all prefer different textures. It is also worth noting that this evaluation relates only to this formula, there are many ways to alter a formula's aesthetic and it's likely any down-sides pointed out here can be eliminated by optimising the formula to that emulsifier.

| Ranking | Feature | ||||

| Flow Elegance | Soaping on rub-in | Immediate skin feel | Delayed skin feel | Appearance | |

| 1 | Emulium Kappa | Glyceryl Stearate Citrate | Cetearyl Alcohol/ Ceteareth 20 | Emulium Kappa | Emulium Kappa |

| 2 | Glyceryl Stearate Citrate | Emulium Kappa | Emulium Kappa | Emulsifying Wax Vegetable | Emulsifying Wax vegetable |

| 3 | Cetearyl Alcohol/ Ceteareth 20 | Cetearyl Alcohol/ Ceteareth 20 | Glyceryl Stearate Citrate | Cetearyl Alcohol/ Ceteareth 20 | Cetearyl lcohol, Ceteareth 20 |

| 4 | Emulsifying wax Vegetable | Emulsifying Wax Vegetable | Emulsifying Wax Vegetable | Glyceryl Stearate Citrate | Glyceryl Stearate Citrate |

Based on the samples produced, the clear winner from an aesthetic perspective was Emulium Kappa.

The emulsions were evaluated for their rheology (how elegantly they flow and spread across the skin), their potential to soap-up on rub-in, their immediate and dry-down skin feel and their general appearance.

The Emulium Kappa produced a rich, glossy cream with medium viscosity, suitable for a pot, pump or tube. The cream felt elegant and silky on application, rubbed in well with minimal soaping and dried down to leave the skin feeling soft and protected. The others emulsifiers scored about half as well as the Kappa, each having their own benefits and drawbacks.

A detailed break-down of the testing and results can be found on the following pages.

Rheology and Viscosity:

Rheology

How a product flows (smooth, gluggy, jelly-like etc.)

Viscosity

How viscous (thick or thin) a product is.

It was obvious from visually comparing the samples the emulsifier chemistry influenced the sample viscosity. Initially the samples ranged from a low of 9,000 cps which is lotion-thin through to 42, 810 csp which is just thick enough to package in a jar. On standing for five weeks, the viscosity of all but one emulsion rose (the other stayed the same) resulting in samples ranging from 17,810 cps (a pumpable lotion) through to 44,960.

It is common for emulsions to thicken over the time period just after manufacture. This process can take between one and ten days depending on how the product was made, the storage conditions during this time and which emulsifier is used. After this point the viscosity typically remains fairly stable until the product experiences a physical, chemical or microbial change to its composition. We tested viscosity on day 0 (the day the samples were made) and at the five-week mark and made a comparison.

While the rise in viscosity for three of the samples was as expected, the degree of increase was a surprise (30-50% increase on starting point). This dramatic thickening over time is likely only to be of interest to the product manufacturer and packer as most end-users will receive their packed goods well after the product is manufactured (and therefore settled). But if you are the product manufacturer, this type of information could be both time and sanity saving – no point stressing too much over the initial viscosity, just wait until it's settled!

The Emulium Kappa was an anomaly in this regard remaining largely static in terms of viscosity over time. This could be highly beneficial in a just-in-time manufacturing environment or when creams are made fresh to order (custom blends/ compounding etc) where the end user receives the sample within that five-day window.

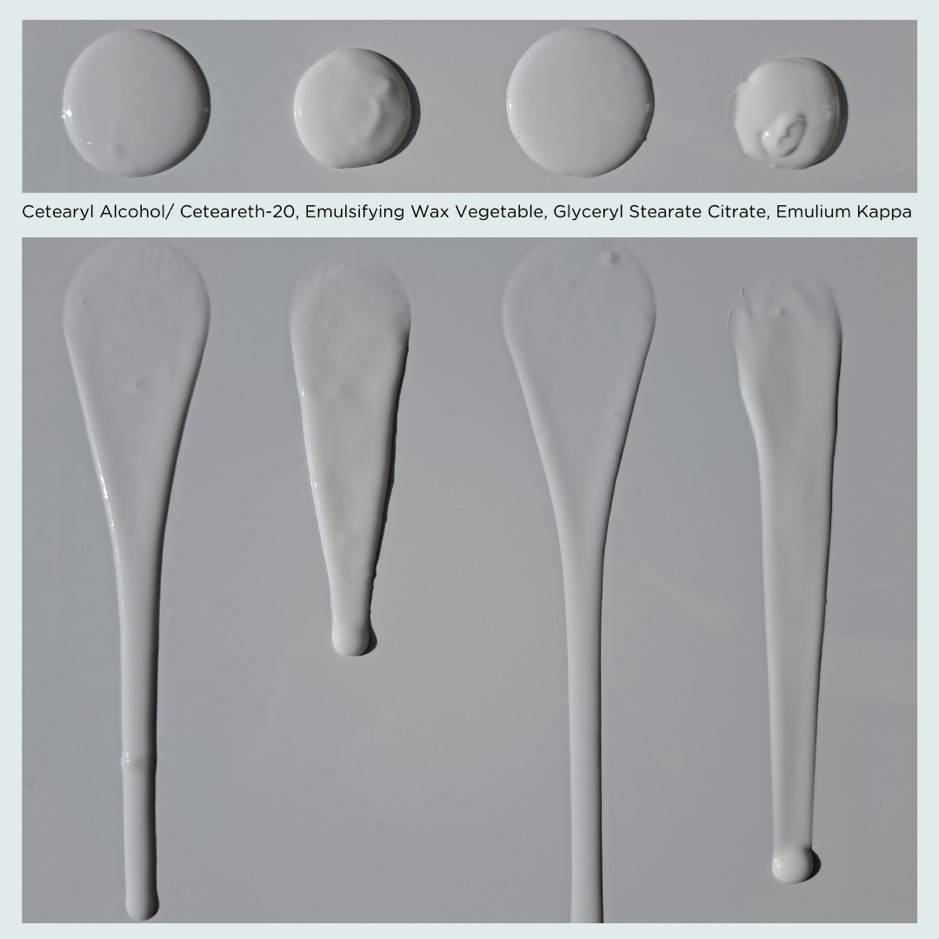

This picture shows the rheology or flow of the creams. Creams were placed on a tile them filmed sliding down as the tile was moved from flat to a 90-degree angle.

While the Emulsifying Wax Vegetable and Emulium Kappa have virtually the same viscosity (thickness), the Kappa travelled much further during the test. The Kappa emulsion has a lower Specific Gravity (lighter) than the Emulsifying Wax Vegetable. Maybe that is a factor in how the samples respond to gravity. We would need to do more testing to find out.

The On-The-Skin Analysis

The potential for an emulsifier to cause soaping in a formula is another key metric. Soaping is when a cream turns white and 'soapy' when you try and rub it in - it does the opposite to sinking into the skin really. This happens when a formulations surface-tension is too high ie: the oil and water prefer to hold onto each other than break apart and sink into your skin.

This can happen when there is an excess of emulsifier, when a formula contains too much gum or when there is a lot of wax in the oil phase. Soaping isn't something that some emulsifiers do and others don't (ie: you can't just source a non-soaping emulsifier), it's formulation dependent so emulsifiers that soap a lot in one formula setting will not in others. So in this regard a bad performer wouldn't necessarily warrant us abandoning the emulsifier in question, more that we'd have to perform some formulating tweaks to relax things a little and increase the spreadability. In our experiment the Vegetable emulsifying wax and ceteareth-20 blend soaped up the most during rub-in and the Glyceryl Stearate Citrate performed the best.

An alternative way to view soaping in the context of a laboratory project like this is as an indication the emulsifier is present in excess (too much) or, to put it another way, the emulsifier may be too powerful to use at that level (3% in our formula).

How The Emulsions Felt

Evaluating the emulsions is typically done by measuring the same amount of each sample out and then applying it either to the back of the hand or the inside of the arm for evaluation. The reviewer notes the initial feel, how it rubs in (the soaping etc) and how it dries down (or sinks in).

In this evaluation the best scores are given to creams that glide across the skin smoothly, rub in with little to no soaping and little pressure, have little-to-no tackiness on initial application and dry down quickly to give a soft, moisturised skin feel and appearance.

This aesthetic would not be ideal for all emulsion types but is desirable for most day-wear emulsion products.

The emulsifying wax vegetable left the skin feeling most tacky on initial rub-in but it redeemed its self somewhat by drying in well, leaving the skin feeling soft and non-greasy. The glyceryl stearate citrate sample had the waxiest skin feel both initially and after dry-down - a feature that's useful in protective barrier creams and products for dry-skin but less desirable for light-touch moisturisers and products for normal to oily skin. The overall winner in this round of testing was Emulium Kappa which scored well in both initial and dry-down skin feel, leaving the skin with a smooth, non-shiny finish.

Experimental Findings From the Inside Out

This round of testing involved evaluating the cream samples under the microscope and looking at the structure. It can be difficult to work out what you are seeing under a microscope at first, but evaluating many different emulsions and then mapping what you see there to what you see, feel and measure in the whole sample can help make sense of it all.

How Viewing The Inside of an Emulsion Helps Us Predict Product Stability and Skin Feel

We describe an emulsion as being homogenous when their internal phase contains dispersed droplets that are very even and uniform in size.

None of these cream samples were homogenised during preparation and instead were just mixed using a laboratory grade propeller mixer. This method was chosen to most closely emulate what a start-up or small brand owner manufacturing their own products might achieve. Homogenisers are expensive to buy and as such are often not part of a manufacturing procedure until a brand grows or out-sources to a factory scale.

Dispersed phase homogeneity is a great indicator of long-term stability and we can see a whole range of particle sizes in these non-homogenised samples. Here we are evaluating the emulsifiers capacity to form a homogenous internal structure without prompting.

Particle Size and Skin Feel

The average particle size of the dispersed phase can impact how oily or elegant the emulsion feels.

The emulsifier that created both the smallest average particles size and those with the highest level of homogeneity was the Emulium Kappa with Glyceryl Stearate Citrate a very close second. The main difference between these two options when applied was in the after-feel. Glyceryl stearate citrate left a more substantive, waxy film on the skin whereas Emulium Kappa left the skin feeling lightly protected and soft. At the other end of the scale, the Emulsifying Wax Vegetable and Ceteareth-20 emulsifier created internal phases containing a broad range of particle sizes.This doesn't mean these emulsifiers can't form homogenous emulsions, rather it means that out of the four tested, those two benefit more from the homogenisation step.

Particle Size and Product Performance

In emulsions containing actives that are soluble in both the oil and water phase, a homogenous product performs better at delivering an even layer of these actives across the skin. While this is often an invisible element of formulating - one our actives are in a product we can no longer see them - it's of key importance. An active may irritate if it applies unevenly with some skin receiving too much and other skin receiving none at all. In other cases, actives that are in non-homogenous emulsions may not be as well protected from oxidation. Overall the time taken to set up and familiarise yourself with this analysis pays off greatly and can ensure you only take your best samples forward for full stability and scale-up.

How The Emulsifiers Changed The Internal Structure of The Cream

Stability and Internal Structure

In both the cetearyl alcohol and ceteareth 20 and emulsifying wax vegetable samples, microscopic analysis showed the presence of chain-like structures between each dispersed oil drop indicating a three-dimensional oil droplet network. This wasn't seen in the other two variants.

These structures are cetearyl alcohol bridges and these contribute both to the emulsions' viscosity and higher soaping potential. In forming these bridges, cetearyl alcohol creates another layer of structure within the emulsion. This increases the emulsions surface tension (resistance to flow) which both boosts the creams physical stability and increases the potential for soaping.

Both Emulsifying Wax Vegetable and Cetearyl Alcohol, Ceteareth-20 emulsifier displayed thick, rainbow-coloured rings around the dispersed oil drops. This was in contrast to the Glyceryl Stearate Citrate and Emulium Kappa which displayed either fewer rings or thinner rings around the oil drops. These thicker rings point towards there being a thick layer of emulsifier at the interface. It may be that both of these emulsifiers are present at a level that's excess to their requirements. We could repeat the experiment with half as much emulsifier and re-look at the slides. Too much emulsifier can be expensive, can (ironically) destabilise an emulsion by it becoming too waxy and can even make the product more irritating to the skin.

The number of visible oil drops was another interesting feature of this experiment and is something the emulsifier plays a large role in. The size and shape of the emulsifier helps determine how big or small the dispersed oil drops can get. We could say the emulsifier choice influences how many droplets you get while the quantity of oil in the dispersed phase determines how large each of those droplets grow.

It would be unusual for a brand to create variants in their cream range by changing the emulsifier but it is clear that changing the emulsifier can change the whole aesthetic of a cream!

Click on below image to download the formula used for analysis in PDF format.

A Final Word

This experiment has demonstrated what a large influence emulsifier chemistry has on how your skin creams are perceived and how they perform both over the short and long term.

It is hoped that this data will help you start to make the connection between how your emulsion looks and feels and what is going on inside so that you can push your formulation further in a more measured and informed way. We also help that this will give you more confidence in trying out new emulsifiers and performing your own comparative analysis in order to find the best fit for your clients and personal needs.

Amanda Foxon-Hill