News

Articles & Recipes

Articles

How Encapsulation Can Enhance The Efficacy of Y...

News

Articles & Recipes

Articles

How Encapsulation Can Enhance The Efficacy of Y...

How Encapsulation Can Enhance The Efficacy of Your Essential Oils

If only it were always that simple...

Essential oil chemistry is volatile, it has to be in order for you to smell it but in some cases that volatility stretches beyond the aesthetics of just delivering the aroma molecules to your nose. When the volatility turns inwards we can end up with some consequences that are less welcome.

Essential oils often contain natural weak spots - chemistry within their mix that is triggered into undergoing changes either by the formula it is placed in or environment in general. One of the most talked-about changes that occurs is oxidation, that is where one or more of the essential oil's aroma chemicals is chemically robbed of electrons making it less balanced and stable. While it is hard to imagine a tiny reaction like this taking place, we see examples of oxidation every day - when metal rusts or when apple cores or avocados brown after cutting. Oxidation reactions will happen naturally over time no matter how well you store your essential oils. Our hope is always that we can stave off any changes for as long as possible so that we can enjoy our oils and rely on them throughout their reasonable shelf life. However, sometimes these reactions happen faster than we would like, especially in cosmetic products where there is a lot of water and other natural oxidation-prone ingredients. Further, for a few essential oils this oxidation can make what was a very gentle and non-irritating oil, quite a lot more likely to cause problems. Lavender is one such example.

Lavender essential oil is Generally Regarded as Safe (GRAS) in terms of its irritation potential. However, that status refers to its un-oxidised or fresh state. As lavender oil ages two key components, linalool and lineally acetate can oxidise and when they do, they become more irritating to the skin (Bråred Christensson et al., 2012, Sköld, Hagvall & Karlberg, 2007). Linalool oxidation occurs spontaneously over time when the oil is exposed to air whereas the oxidation of linalyl acetate tends to occur in the presence of peroxides. Peroxides can form in a formula as other ingredients break down so it may be that one of your carrier oils starts to go rancid and the free radicals released into the formula because of that kick start the oxidation of linalyl acetate in your lavender. More information on essential oil chemistry and stability can be found in Robert Tisserand's book 'Essential Oil Safety' (Tisserand, Young & Williamson, 2014) which is available for purchase at New Directions.

Protection of essential oils in a product comes in many forms and a formulator will consider all of these things in the R&D stage. The use of appropriate antioxidants to reduce and/or slow down oxidative chemical changes (over the nominated shelf life) is a common step. Most people who put recipes and formulations together will have noticed there is nearly always a 'vitamin E' step these days. Not so long ago, vitamin E was less common and instead, the petroleum derived BHT/ BHA antioxidants predominated.

Tocopherol (vitamin E) in its mixed state (Alpha, Beta, Gamma, Delta Isomers) is a pretty good formulation partner in this regard being relatively cost effective, long-lasting (much more stable than BHT/ BHA), readily available and easy to incorporate. However, it's not perfect, has a slight to sometimes quite strong odour of its own and an oil solubility that is logical and necessary for its function but makes it hard to combine into a spritz spray formula due to its effect on the dispersed phase solubility. Other options are available to compliment or replace vitamin E including Rosemary Antioxidant and then Ferulic Acid, Symsave® H (hydroxyacetophenone, Vitamin C (although this is often the first thing to oxidise as it's very unstable compared to vitamin E), Coenzyme Q10, plant polyphenols, Alpha Lipoic Acid and many more besides some of which will be present in your plant based actives and others you may add specifically or even top-up to ensure good product protection coverage.

As good as loading up a formula with antioxidants is, it isn't always the answer to your formulating problems, especially when you wish to achieve a very long shelf life (in excess of 24 months maybe) and/or have a very natural or very naturally active formula.

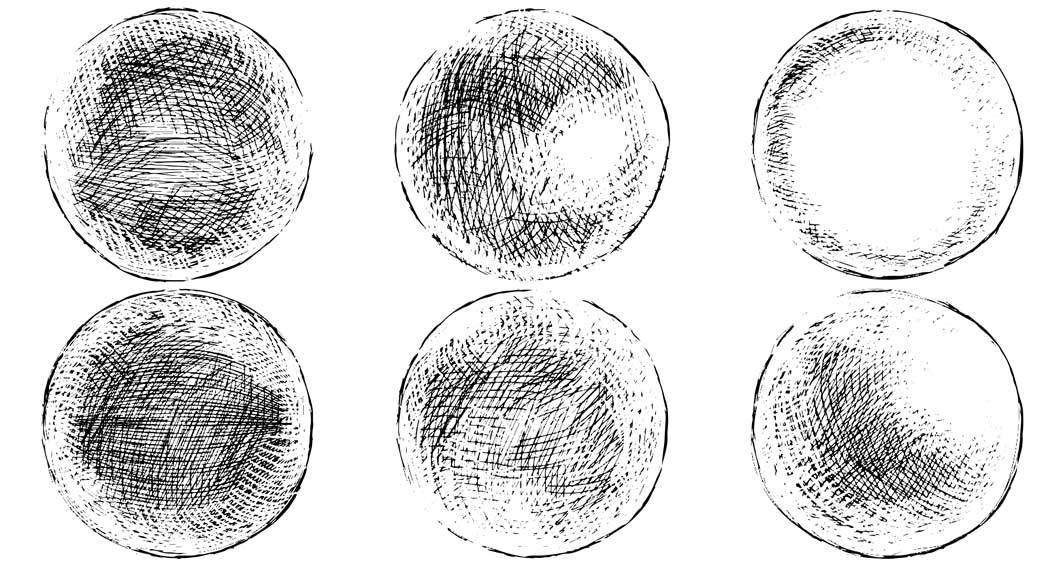

Sometimes you just want to curl up inside a little bubble and forget about the world...

An alternative strategy for active (including essential oil) protection is encapsulation technology. Here the active is protected from oxidation and other environmental stressors by wrapping it up in a shell. This technology has been successfully used to protect volatile chemical mixtures such as essential oils and other flavour and fragrance combinations across food, pharmaceutical and cosmetic industries and again, while it may not be the perfect solution for every formula, it is well worth diving into.

If we think of a formula as a battle ground where oxidation is the attacking force, your antioxidants act like armour for the good guys. However, the good guys are still out there and no matter how good the armour, given enough time out on the battle field the good guys will get tired. Encapsulation technology is like putting your good guys into a cozy waiting room away from the front line. While they can't sit in that room for ever, there's every chance that they can wait it out for long enough for you to have a decent shelf life.

Applying that technology to Lavender - CelluOil™

CelluOil™ capsules are supplied as a free flowing fine powder. These particular capsules contain Lavandula Hybrida Abrial oil at a concentration of 50%, in a modified cellulose shell which is chemically and biologically inert so as not to negatively interfere with the efficacy of the active or the formula. The shells are an example of 'release-on-demand' technology ensuring freshness and maximum efficacy over the product shelf life whether formulated into a serum or a cream base.

Encapsulation technology such as this gives you greater formulating freedom to including fragrance layering (where the initial in-pack smell changes to a more lavender based aroma on rub-in), higher essential oil dosing without the over-whelm or even the development of neutral base odours that burst into life on application.

While there are many different encapsulating technologies available to the cosmetic chemist, this particular technology caught our interest at New Directions Australia due to its capacity to perform well across a wide range of temperatures, pH ranges and oxidative environments. As the polymer shell is unreactive, a much wider range of actives can be carried with this technology and at payloads of up to 90% depending on the active. The fact that the shells can be combined easily into most formulations and deliver a pleasing in-use aesthetic meant that we just had to give these a try!

You can find CelluOil™ for sale as an ingredient on our website or you can try it for yourself in our night cocoon sleep mask. In this product we've paired the stabilised lavender with Hyaluronic acid and Ceramide complex for a silky rich restorative night treatment that, upon rub-in will both soothe your skin and help you relax ready for that much prized beauty sleep.

We hope you enjoy experimenting with this exciting new active and product combo and if you need help stability testing your cosmetic creations do let us know as we have a stability testing service available for clients.

Amanda Foxon-Hill

28 January 2020

References:

- Bråred Christensson, J., Andersen, K., Bruze, M., Johansen, J., Garcia-Bravo, B., & Gimenez Arnau, A. et al. (2012). Air-oxidized linalool-a frequent cause of fragrance contact allergy. Contact Dermatitis, 67(5), 247-259. doi: 10.1111/j.1600-0536.2012.02134.x

- Home - Robert Tisserand. (2020). Retrieved 24 January 2020

- Sköld, M., Hagvall, L., & Karlberg, A. (2007). Autoxidation of linalyl acetate, the main component of lavender oil, creates potent contact allergens. Contact Dermatitis, 58(1), 9-14. doi: 10.1111/j.1600-0536.2007.01262.x

- Technology full TAGRA. (2020). Retrieved 24 January 2020

- Tisserand, R., Young, R., & Williamson, E. (2014). Essential oil safety (2nd ed.). Edinburgh [etc.]: Churchill Livingstone/Elsevier.