News

Articles & Recipes

Articles

Good Manufacturing Practice For Start-Ups

News

Articles & Recipes

Articles

Good Manufacturing Practice For Start-Ups

Good Manufacturing Practice For Start-Ups

If you are going to be making big batches for yourself the first thing to think about is the integrity of the facility. Ideally you will have a room or area set aside for manufacturing that is otherwise clean and free from anything that can gather dust or become home to pests. Hard, hose-able surfaces are best such as tiles, sealed concrete or stainless steel and ideally there will ventilation in the room to keep your air quality high.

It is a great idea to store your raw materials separately from your main manufacturing room just so they don't become contaminated if a batch spills or if dust gathers on them.

Once you have a clean, nook and cranny free room organised it is time to think about the equipment.

Stainless steel bench tops are lab friendly but labs also use high quality kitchen style work tops (melamine) that are acid and alkali resistant (at least to a point). Wood is not ideal as it is porous and can be very hard to clean.Ideally your bench tops should be flush to the walls so as not to provide spills with areas to fester.

|

As far as equipment goes you are far better to get entry-level cosmetic grade mixing equipment (propeller mixer, homogeniser) than a good kitchen aid. This is because unlike most food cosmetics have to stay fresh for a long time and so any residual dirt can severely shorten your products shelf life and food mixers (such as your average bar mix) are notoriously difficult to clean. Mixing bowls etc can be anything really as long as they can be cleaned and sanitised but be wary of cheap glass if you are planning to heat things up in it. Glass should be laboratory grade so that it heats and cools evenly without shattering. Spoons and spatulas should be set aside for cosmetic manufacture only and not food. It is also a good idea if possible to have a laboratory-only dish washer to help you keep everything clean! |

Now that you have your room ready we should think about our ingredients.

|

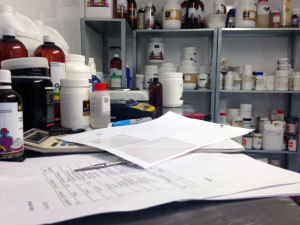

Ingredient control can be tricky as very few small businesses have a computer system to check ingredients in and out of their factory and make sure everything is in date and is the ingredient you wanted it to be - mistakes do happen! We suggest using a simple excel spreadsheet or setting up your own small database to log your ingredient purchases and batch numbers. Batch numbers are important as a way of tracking what is going into your finished products and can also help you pick up purchasing errors, supplier mistakes or even to alert you to a change in ingredient smell, colour, shape or texture.Natural ingredients are notoriously difficult to work with due to batch to batch variation so keeping track of this on a per batch basis might help you explain why one lot you made was yellowish while another came out white.Batch numbers can also quickly reveal to you if you have used an ingredient that is out of date - another common cause of batch failure! |

In a large company manufacturing situation batch numbers of stock to be used are recorded on your formula batching sheet both for the quality control and tracking reasons above and also as a way of insuring that you have picked the right ingredient in the first place. Formulations containing lots of similar sounding or complex ingredients do require a careful eye and having to carefully double-check a batch number will help you stay on the right tracks.

So you have printed off your formula,found your ingredients and are now ready to manufacture...

Now is where the fun begins but to avoid turning it into a financial nightmare we suggest you

- Pop on your lab coat, covered in shoes, gloves, hair net and beard net if you need one. Yes you will look like something out of a horror movie but these things will help you keep your batch clean. Also make sure you have taken off any jewellery and false eyelashes and nails!!!!

- Re-check your equipment for dust and dirt. Flush out where necessary and use anti-microbial cloths or solution to sterilise your workspace.

- Use your formulation sheet to keep you on top of what you have and haven't added into the batch by ticking off as you go. You would be surprised at how many times the phone goes when you are just about to put in the beeswax then half an hour later you are standing there thinking 'now did I or didn't I'. Checking each ingredient off like this also ensures you don't put the wrong thing in as it encourages you to read the labels as you go!

- Use calibrated scales. If you are manufacturing for business you really should get your scales checked over or calibrated to ensure you are weighing everything correctly. You can perform a check yourself by buying standard weights and using them to just keep an eye on things in between audits.

- Use a timer or stop watch/ clock to help you keep track of how long things are mixed, heated and cooled for so that you can carry out process improvements over the long-term and in the short-term can ensure you are doing things the same way each time.

- If you have various mixers or attachments do keep notes of which ones you used as this can also have a big impact on your finished batch.

- Keep notes of how long the product took to cool down and finish off if necessary as this is really important when assessing micro-stability. If you left your batch for 2 days before putting the preservative in then there is no wonder that it failed micro...

- Take a picture of the batch and store that with your batch sheet as sometimes a visual will help you remember more than written notes.

- Weigh your batch and record your yield, making notes of any noticeable reasons for losses - left on blade of mixer, spillage, evaporation etc.

- Pack and store in a safe, clean, dry spot away from direct sunlight.

- Give your product a batch number and record it! There are no hard and fast rules over what a batch number should look like but we suggest making sure you can tell the date, amount made and formula name from the batch number as a minimum.

- Get down with the cleaning! Cleaning solutions can be tricky to gauge. We suggest a good soap and water wash down to clean away visible dirt followed by copious rinsing, air drying then spraying with an alcohol solution. Anti-microbial solutions can be added after the bubbly wash if you want to be extra careful as while alcohol is great it can't kill everything. Clutter, dead legs in pipework, nooks and cranny's and poor air quality are some of the biggest issues in cosmetic manufacture but if you can cover these you should be OK.

One last thing is water. It goes without saying that you need to take care to use good quality Demineralised Water. Demin water is best for cosmetics as it contains nothing for the microbes to feed off. It is also very pure and so won't (or shouldn't) interfere with your emulsifier or surfactants. If you are purchasing your Demin from a store rather than making it fresh with a filter we recommend purchasing in pack sizes that will suit your batch or be used up quickly as a half used bottle of water, especially once the lid is left off is a recipe for disaster!

It is possible to manufacture from home well, one of our contacts who makes dog shampoos returned excellent results in her Preservative Efficacy Testing recently, better than many of the factories I visit! However, manufacturing from home well and for profit does require some commitment to the process from stock management through to saying goodbye to your cosmetic babies as they get sold out into the big wide world.

We think it is worth the effort, don't you?

Amanda Foxon-Hill

28 July 2014