News

Articles & Recipes

Articles

Plastic Packaging - What Choices Do Cosmetic Br...

News

Articles & Recipes

Articles

Plastic Packaging - What Choices Do Cosmetic Br...

Plastic Packaging - What Choices Do Cosmetic Brand and Business Owners Have?

Worldwatch Institute, Jan 2015.

The outrage that was felt when somebody, somewhere realised that some of the exfoliating micro beads found in cosmetic facial and body scrubs were sometimes made from little pieces of plastic was interesting given that the majority of the aforementioned products were packaged in more plastic than the beads could ever be responsible for. However, it caused a stir that went all the way up to government level in many countries around the world and resulted in a dramatic change in scrubbing behaviour - plastic scrub beads are now a very dirty word. As great as this growing awareness to materials and their life-cycle is, it does beg the question 'what about the packaging' and more specifically 'what choices do cosmetic brand and business owners have'. Where are we up to with all that?

299 million tonnes of plastic was manufactured in 2013, a 4% increase on 2012 figures.

This plastic accounts for 4% of global petroleum consumption.

Between 22-43% of plastics end up in land fill and 10-20 million tonnes ends up in the oceans each year.

Figures from Worldwatch Institute.

Plastic. What's used now?

When purchasing a new bottle or jar the material that the vessel is made of is often given less thought than the containers shape, price and availability. As important as those things are, the material used to make the container is worth thinking about given the close contact it has with your product and the potential it has to either increase or decrease its shelf life and usability. Not only that but some plastics are better suited to hot fill products than others, some are more resilient, more squeezable, tougher, more UV protective and easier to handle. All that has to be thought of before we jump into what will happen when we throw it away.

Product / packaging interaction is one aspect of stability testing. Product is usually stored in lab packaging (glass) and the customers final packaging choice to enable the tester to see if the final packaging helps or hinders with product stability, whether there is any discolouration, cracking or leakage upon storage in different conditions. Packaging testing is important for all types of product but is especially useful in products that rely on their packaging to function - spray bottles, deodorant rollers, stick products and pump packs are some examples where the packaging has to physically dispense the product in good order to allow it to fully function. Where packaging affects chemical stability is to do with oxidation as we will see below. Some packaging is able to form a better barrier to oxygen, UV and moisture than others and sometimes it will be the packaging that makes the difference between a stability pass and fail. With that in mind it seems clear to me that getting the packaging selection right in the first place is the first step to being an environmentally responsible brand owner. Right packaging = better performing, longer lasting, more satisfying product and who doesn't want to be that brand where people break open the packaging to scrape the last drops of product out!

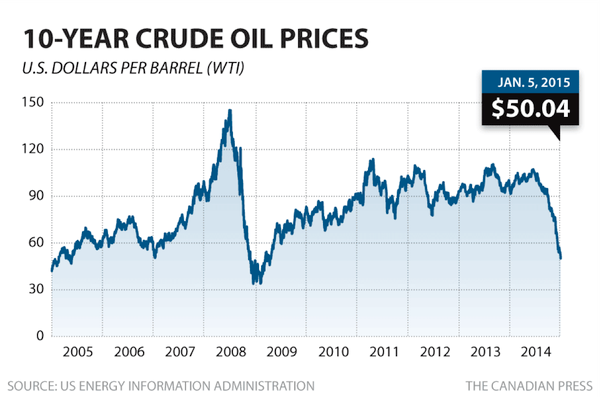

But what happens when you've got your bottles and used up the product. Is what we currently use recyclable? It pays to remember that recycling is an evolving industry and one that tends to grow and evolve more quickly when the virgin oil price is high. When oil prices are low it can be quite tricky to make recycled materials financially attractive which is a shame for everyone but can be quite devastating for brand owners who want to do the right thing but have a ceiling price on their finished goods. Let's have a look at the different types of recyclable packaging used by cosmetic brands today.

PET (Polyethylene Terephthalate)

Cheap, lightweight, easy to recycle:

When it comes to product integrity over its shelf life PET does not give your product the best protection due to its relatively high oxygen permeability. PET manufacturers are constantly innovating their product and trying to capture some of the glass bottle market with their PET products. This may sound like a bit disaster for people looking to reduce plastic use but one has to weigh up the costs of transportation for glass vs plastic in calculating environmental impact which makes things far less clear cut! The permeability challenge faced by PET manufacturers is something that will eventually be resolved with multiple layered light-weight bottles looking to replace the current system.

With regards to PET bottles, at least one of the manufacturers here in Australia has made a commitment to use recovered PET in new bottles at levels between 25-100% which is heartening as every bit of re-used plastic reduces the burden on virgin material. This also goes for HDPE.

PETG (Polyethylene Terephthalate Glycol). Recyclable under code 7.

Tough, high level of chemical resistance (alcohol, acetone solvents), more flexible in manufacturing (so more creative bottle types and shapes are possible)

HDPE (High Density Polyethylene)

Versatile, low risk of leaching into the product. Usually for harder packaging than the PET but not always.

Readily recyclable and hardy. Far better at preserving product integrity than PET so best for cosmetic products that might perish from oxidation - Essential oils as actives/ aromas, Retinol products, Vitamin C serums etc..

Again at least one Australian packaging manufacturer has made a commitment to incorporate between 25-100% reused HDPE into new packaging.

PVC (Polyvinyl Chloride)

Tough and withstands harsher environmental conditions than PET. Flexible plastic food wraps (such as Australia's Glad Wrap) are made from this. Requires a high percentage of pthalates to plasticise (soften) it so is a potential source of pthalate contamination in a product if the product leaches into the packaging and vice versa When it comes to cosmetics PVC is better than PET at protecting a product from oxidation due to its lack of permeability to oxygen but it is less likely to be used due to the potential for leaching into the product, especially when essential oil based fragrances and actives are used although that's not to say that all PVC packaging is unsuitable with essential oils.

LDPE (Low Density Polyethylene)

This is a flexible plastic often used for tubes. LDPE is often blended with other materials to get the right mix of flexibility, stiffness and durability. It may also be lined with EVOH (Ethylene Vinyl Alcohol Copolymer) to improve oxygen permeability. As long as the tube has the recycling symbol it can be recycled. The cosmetic brand owner/ formulator needs to specify the tubing requirements so as to protect the formula inside and often tube manufacturers will help brand owners decide on which types of tubing to go with although all will insist on stability testing to confirm their diagnosis which is fair enough given the complexity of most cosmetic formulations.

PP (Polypropylene)

This is great for hot fill products due to its high heat tolerance. This makes it great for balms, waxes and pomades. It also has a pretty good oxygen barrier and is often a hard pack so suitable for ridged jars.

PS (Polystyrene)

OK so Polystyrene is not often used as a primary (or secondary) packaging material in cosmetics but it can often be used to help ship your ingredients around! Polystyrene often comes at you in those little cubes that stop your herbal extract bottles rattling around in the box during shipping - we still use it here at New Directions as while we would dearly love to find a less 'plastic' option for packaging, nothing on the market currently beats this materials properties.

Polystyrene is useful in as much as it can be made super hard and non-squashable yet ultra-light weight meaning it can fill those empty box spaces well without adding weight. While it is recyclable it has something of a bad public image due to it often being used in disposable cups and take-away trays making it look cheap, nasty and polluting. It is also quite often NOT recycled even though, technically it can be. It's low recycling rates are due to its weight issues. On a large-scale, its large volume to weight ratio (takes up lots of space, not very heavy) means it can be very un-economical to transport to recycling plants. , store or dispose of (into a skip bin). That does look likely to change very shortly though as it is now possible to hire machines that crush polystyrene to reduce its volume and make it more economical to ship to the recyclers and there is even an Australian company that hires out machinery to do just that. In order to finish the job the squashed and crushed polystyrene can be further processed by one of the 14 polystyrene recyclers already in operation within 60 kilometers of Sydney's CBD. Things are indeed looking up!

Others including PETG and Polylactic Acid

Polylactic acid is one of a newish breed of biopolymers, plastics made from vegetable starting points rather than petroleum. As a stand-alone polymer Polylactic Acid is very brittle and requires plasticisers to help it be moulded and squeezed. In terms of oxygen permeability PLA is reported to be somewhere between PET (better than) and PVC (not quite as good). This study on oxygen permeability of PLA found, as you would expect, that the thicker the PLA material, the stronger the oxygen barrier. I found this simple and somewhat logical graph clicked something in me though, we try to make plastics thinner so they use less material and are more efficient but in doing so we might well increase their oxygen permeability to a point that they can no longer perform well for us - a balance between packaging thickness and packaging performance has to be met. On further reading it turns out that there is an optimum amount of plasticiser to be added that further increases the plastics tolerance to oxygen. Adding more plasticiser goes on to reduce oxygen tolerance. Again, simple science really but interesting as it shows the limits and tolerance of different polymers to different conditions.

Just one other thing around PLA is its heat stability. Like PET, PLA is not that heat stable and can deform at temperatures of 60°C and up which puts hot filing out of the question. This can make PLA bottles unsuitable for some cosmetic applications.

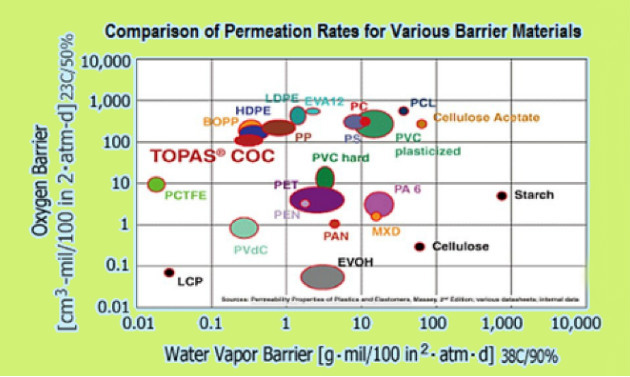

Here is a useful graph comparing different types of packaging in terms of their oxygen

and water vapour barrier properties.

So nearly everything we use can be recycled. So what's the problem?

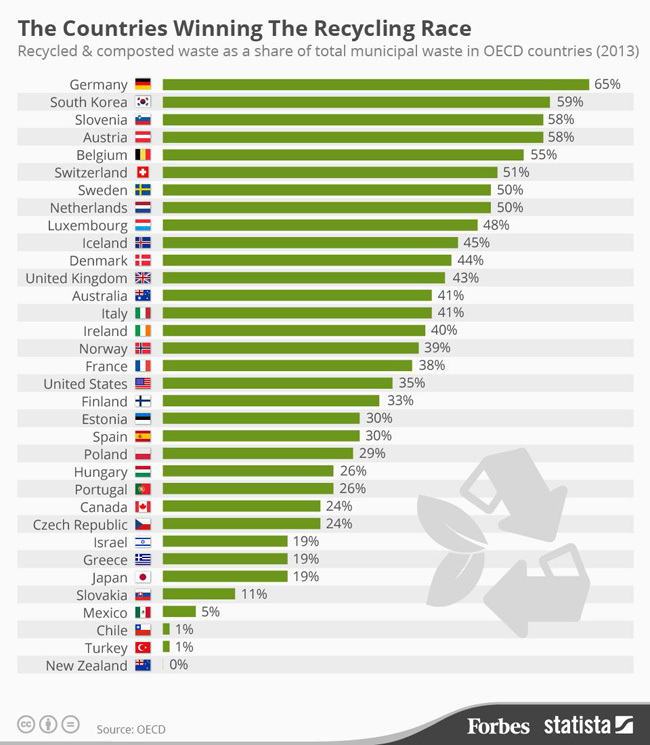

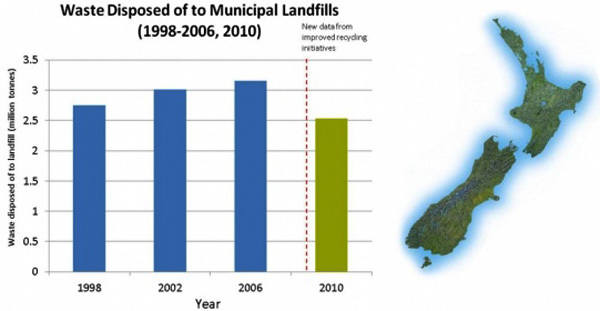

Not everything that CAN be recycled IS as we can see from the graph above. When I found this chart I immediately questioned why New Zealand was at the bottom as that looked odd to me but apparently they did have quite a bad record in recycling up to around 2008 when Parliament started to take things a bit more seriously. Apparently at that time it was costing 10 times more to send something to landfill in the UK than New Zealand so quite simply, chucking it in the dump was just too cheap in NZ. The price paid to dump stuff is entirely political so it is right for politicians to manage this.

The barriers to recycling are many including the availability and proximity of recycling facilities to waste generation, price of transport, price of energy and government policy/ incentives on waste to name but a few. Some years it makes more sense financially to recycle than create new material while in other years the dollars stack in favour of just making it all afresh. Think of the difference in costs between building your new home on a freshly, clear, level site vs a knock-down and disposal job. During times when global oil prices are low, it would be down to government policy to make recycling more attractive. As you can see below, oil prices rise and fall quite dramatically over time and as bioplastics currently only make up 1% of the plastics market, oil prices still matter hugely!

Petroleum Free Plastics Accounted for only 1% of the global plastics market in 2013

The other big problem with plastic recycling is that you can only recycle so much before you reach the end of the line. Just how many times plastic can be recycled is something I can't entirely answer as it depends on the starting plastic and in what it is subsequently recycled into but often you are talking about only once for bottles (so virgin bottle then recycled bottle) and then it has to be re-purposed into something else. This reality goes for all types of plastic, whether bio or petroleum which basically means that when using plastic packaging its final demise should always be kept in mind and when we think of death we must also think of birth - the circle of life or Cradle to Grave Analysis.

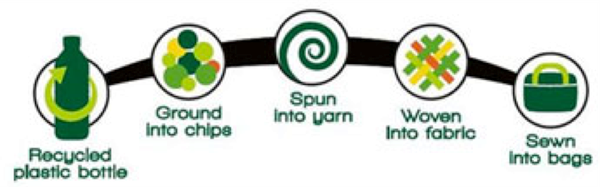

In terms of what 'other' things plastics might become when they stop being bottles we find that quite a bit of it actually comes back as clothing! Again, when looking into the plastic microbeads issue I was blown away by the fact that I was often WEARING much more plastic than I was ever putting on my face (or even counting for the plastic in the product bottle).

25 x 2 litre bottles = 1 fleece jacket. Made from Polyester or Polar Fleece

Degradation times:

- Cotton glove: 3 months

- Wool: 1 to 5 years

- Leather shoes: 25 to 40 years

- Nylon: 30 to 40 years

- Rubber boot sole: 50 to 80 years

Other companies such as this one take plastics and rubbers and turn them into more durable products such as park benches, play matting, decking and fences thus extending the usable life of the plastic and diverting it from landfill.

Bio-Polymers - Are they a good choice?

Rather than answering this with a personal judgement call I want to look at the subtleties and facts again.

Petroleum is going to eventually run out as it is a fossil fuel that we use faster than we can make so we HAVE to find alternatives which we are doing with our bioplastics typically made from corn starch, rice husk, bamboo fibre, palm leaf, sugarcane and wheat straw.

Bioplastics are renewable as they grow fast and can be re-grown for as long as the soil is viable and available and water is present in the right quantities. But if we stop and think on that for a moment it doesn't take long to realise that land availability and water security are also hot environmental issues for us right now.

An Aside: My thoughts here are that we could find ourselves in a 'Palm Oil' type position if we don't do some proper joined-up thinking about this right now - we all jumped on board the palm oil wagon for cosmetic ingredients when moving from petroleum and tallow to vegetable feedstock, we felt good about that and ended up consuming MORE product (and arguably valuing the resources less because they were so cheap). If we do that with bioplastics we will end up in real trouble as both packaging and product will be competing for land (including land currently used for food crops) and water resources.

But don't bioplastics biodegrade better?

Biodegradability is a funny thing and is heavily dependent on the environmental conditions the packaging finds its self in and the definition of biodegradable the product complies to but in any case bioplastic and biodegradable are not one in the same. It is possible to make a bioplastic that doesn't biodegrade and make regular plastics from petroleum that do. The main plus point with bioplastics is the non-reliance in petroleum feedstock, that said, the chemicals used to plasticise or process the bioplastics are likely to be petroleum derived (and may be present up to 40% of bulk weight, so a bioplastic might represent a 60% 'saving' as a minimum on petroleum resources).

Biodegradable plastics are plastics that are engineered to fail (break down) at some point. The plastic manufacturers may incorporate a chemical into the structure that breaks down in certain conditions (UV, moisture, heat, soil etc). So, to re-cap you can buy bioplastics made from corn that don't biodegrade and those that do, just as you can buy petroleum derived plastics that behave similarly.

In terms of biodegradation that is worth a whole other article as plastics might degrade to their monomers but not break down fully. Biodegradable plastics based on Polylactic acid are sold as being able to break down into nature identical compounds that don't pollute the soil, some are even classified as compostable but not all. One might now feel that this gold standard of bio plastic, biodegradable and compostable is the answer for you but be aware that this type of packaging may not yet be available to suit and support the types of products you are wishing to make so while we know HOW to solve the problems we face, we are just waiting for the fixes to become economically viable and widely available. That shouldn't take too long as long as we all remain interested and willing.

Additional options for the cosmetic brand owner to investigate.

Did you know that it is entirely possible to re-create petroleum derived plastics naturally? Without getting too deep into a chemistry lesson petroleum derived plastics rely on a chemical called ethylene which is produced by cracking naptha, a chemical that comes from crude oil. BUT ethylene can also be manufactured from ethanol derived from sugar cane (or corn)! Brazilian company Braskem is the largest manufacturer with 52% market share. Keeping this in mind it might be the case that rather than we all change to DIFFERENT polymers (PLA etc) we stick with PET, HDPE and the rest but create them with vegetables rather than crude oil. In many ways this would be an easier route to take as we have more experience with these polymers than we do with PLA. The only hurdles being (again) the land use food vs packaging issue and the biodegradability profile.

And finally to Waste-to-Art projects. Packaging from Fungi!

OK so this is my favourite option in terms of novelty and functionality and that's plastic made either from mushrooms mycelia or from waste greens as long as its compostable where possible.

Without a doubt in my mind the biggest issue in moving from a petroleum to vegetable economy is land use. If, like me you value forests, countryside and space the thought of a growing global population using land for even more non-edible resource production is actually quite sad-making so I'm super excited at the prospect of turning the bits of vegetables we don't use into up-stream products instead. Now sure, plastics made from plants are already available to some degree you might say but I'm talking about real waste like the stuff you might put into your composting bins OR the actual roots of the fungus that starts decomposing your stuff. That's what I call an exciting use of resources. Again, these types of plastics are not likely to be coming in every shape, size and packaging type to a store near you any time in the near future but in time, I think it will be the way to go - reducing waste AND creating great natural products, a win, win if ever their was one!

On that note I came across an interesting American company, Ecovative, when looking at alternatives for the Polyethylene packing nuggets that are often used. This company actually make their plastics from mushroom mycelium which looks extremely interesting!

Grow it yourself mushroom packaging - not water resistant but could be a good option for postage packs although not currently available in Australia. From ecovativedesign.com

While this isn't a workable solution in terms of a material for your shampoo bottle or face mask just yet it is possibly a contender for your shippers, point of sale displays or packaging boxes and what's more it can definitely be composted after use. I do look forward to a more mushroom type packaging future after reading that even though at present, the company is not able to ship its packaging to Australia due to quarantine restrictions – what a shame! Maybe us Aussies can learn how to grow our own plastic! And on that note I'll wrap things up.

Plastic and the Cosmetic Brand – How are things stacking up?

OK so for those of you wanting to shout ‘yes but there's glass, tin and aluminium packaging out there and they are both infinitely recyclable I'd say yes, but this article has been about plastic in its many guises and formats. Glass is heavy (when compared to plastic) and therefore expensive to ship AND it requires more protecting in shipping to prevent breakages. It can be dangerous in wet and slippery places. Further it often requires a lid of closure or tube dispenser which, is often (though not always) plastic. Aluminium tubes are brilliant for many things except it can be very hard to get them filled (not many people have the capacity for filling and run sizes for packaging purchasing and filling can often be very long) – one point of interest is that Aluminium is extremely oxygen tight so excellent for packing materials that oxidise. Tin is a more expensive material and is less flexible than aluminium so is less likely to be used as tubes but is still an option for some products. Going plastic free is possible but it comes with its own varied challenges that may or may not be ‘worth it' for your brand, so back to plastic.

There is one theme that has come up time and time again when I've been researching plastics for the cosmetic industry and that's the massive amount of innovation and science that is going on in this space. We have new polymers, old polymers made in new ways, old polymers made in old ways but with new additives to make them break down quicker and more besides. As a scientist I'm always drawn into areas of innovation and this, for me is a huge opportunity for just that. I appreciate that some people wish to go plastic free and I accept that in some cases avoidance is a reasonable plan but for those of you with an interest in the science of the mainstream (me) then plastics is where it is at!

I can't personally see a future without plastic but after looking into all of this I feel I have more than enough reasons to feel positive that things are going in the right direction. Now if we can all just help keep the pressure up on governments to maintain investment in this type of material science, recycling initiatives, land-fill and waste charging and valuing our land and primary resources I think the future may well look bright.

Amanda Foxon-Hill

25 July 2017